As the leaves turn colors and sweater weather becomes the norm, many facilities that use steam for facility heating have already started getting their boilers ready for the season. Mechanical aspects of the boiler’s operations should already have been completed by this point, including state inspections, physical cleanings of the tubes and shell, and general repairs by your facility’s boiler maintenance company.

Before you are ready to embark on the long, cold winter, a final check on the state of your boiler water treatment systems is also in order. You don’t want to experience untimely issues that you’d have to correct while your plant is firing full-blast.

Here are some checks to ensure safe and efficient operation of your steam boiler water treatment.

IMPORTANT: Never attempt to fix a mechanical or chemical issue unless you are trained and certified to do so. Safety should always come first. Consult a specialist before starting any mechanical or chemical related projects if you are not trained and certified to perform the work.

Inspect and Examine Chemical Feed Lines and Injection Points

If you see your chemical feed lines begin to experience calcification of chemistry at the injection points, now is a good time to remove, clean, and replace the tubing and injection fittings. In addition to the performance issues associated with leaking fittings and the waste of chemical, this is also a major safety issue for the personnel working around this equipment. This is highly concentrated residue from your chemical feed that, if it gets dislodged and contacts skin or eyes, can cause serious damage.

You do not want to interrupt chemical feed while the boiler is in operation to make these repairs, so do a visual inspection of all the chemical feed lines and stations before they go online. Correct any situation where you find this occurring right away.

Check Pre-Treatment Systems

For the vast majority of steam systems, a water softener is (or at least should be) installed to remove calcium and magnesium ions from your facility’s makeup source prior to being introduced into the feedwater for your boiler. If the softener has not been used since last season, run it through a regeneration cycle prior to introducing makeup water to your steam boiler to verify proper operation. If you experience high iron in your makeup source, running a citric acid-based cleaner through the resin may also be a good idea to keep the resin operating at maximum efficiency.

This is also a good time to run a quick check on the incoming water hardness to see if it has changed at all since the last time the unit was in operation. Softeners are programmed to go into regeneration mode based on incoming hardness levels (usually in grains per gallon). If the water source quality has worsened, it can quickly exhaust the softener’s ability to function before it’s programmed to regenerate. This can leave the boiler susceptible to periods of hard water bypassing the softeners, increasing the chances for scaling conditions in the boiler.

Clean and Calibrate Monitoring Probes

If your steam boiler utilizes an automated surface blowdown controller to regulate the conductivity inside the vessel, it is often best practice to clean the probes and remove any built-up debris now to ensure proper operation down the road. Muriatic acid is often employed in this case. Boiler conductivity probes usually have an 18-month to 2-year life, so it may be a good time to replace them if you cannot hold the calibration.

Review Testing Procedures and Examine Test Kits and Reagents

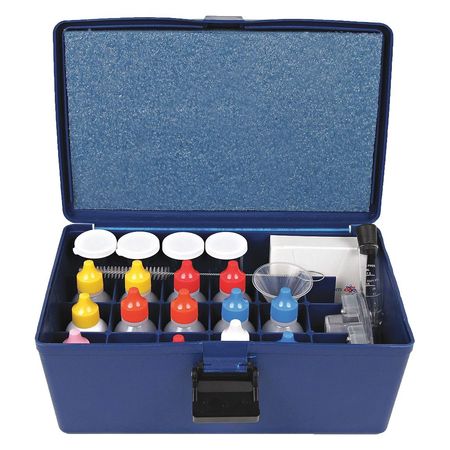

A big key to any successful boiler water treatment program is regular testing by the on-site personnel. And, the testing is only as good as the operators performing the tests and the equipment they are using to test the water. It may be a good idea for your onsite boiler operators to have a refresher from your water treatment provider on the basics of the water treatment program, including how to test for the key parameters and what to do in case chemistry goes out of range. Also, now is the opportunity to calibrate your conductivity and pH testers and to check the expiration dates for the reagents being used to ensure they have not expired.

Inspect Existing Chemical Inventory

Much like testing reagents, your boiler chemical products also have a shelf life. Over time and with exposure to temperature, the delicate chemistry in your corrosion and scale inhibitors can result in coagulated residue at the bottom of your chemical containers, rendering the chemistry less effective. If you have containment tanks that house your boiler products, inspect the bottom of the tanks to ensure they have not collected months or years of old chemical residue that can impact the performance of the replenished chemistry. If necessary, a tank cleaning may be in order.

These are just some “last minute checks” for your water treatment prior to start-up to ensure a smoother operation when operating your plant. Save a link to our blog, “Water Treatment Tips You Should Consider During Spring Boiler Maintenance”, which details water treatment items for the off-season and provides a handy checklist.

Clarity Has the Solution:

Proper water treatment, along with regular inspections and maintenance, can ensure your entire steam system operates efficiently. Additionally, it will reduce unplanned downtime and maintenance costs and will extend the life of your equipment.

Clarity Water Technology has extensive experience with steam boilers. If you have any water treatment questions or issues as you get your boiler ready for the cold weather, just contact our team of water treatment experts.

If you’re in need of water treatment services, Clarity offers our proprietary technology, EcoSHIELD, a cutting-edge treatment for steam boilers that is more effective, economical and eco-friendly than traditional chemical solutions. A water treatment plan that incorporates EcoSHIELD will protect your system and have your boiler running at peak performance. We’ll be happy to conduct a FREE evaluation of your steam system to see how a custom water treatment plan for your facility can save you money!

Download Our FREE eBook Today:

Ten Huge Mistakes Facilities Make in Boiler Operation and How to Avoid Them

Have a question about water treatment and steam boilers?

Check out our steam boiler resource page to find links to helpful articles and case studies that address commonly asked questions.