Your steam boiler is a huge investment that is critical to your facility, so you want to you maximize its performance and longevity. And with the rising costs of the utilities to power your boiler, it is vital to ensure it is operating as efficiently as possible. An effective water treatment program, along with inspections and routine maintenance, can ensure your boiler system operates at peak performance and serves your facility for many years.

How can you tell if your water treatment is working?

There are many ways to directly and indirectly determine the effectiveness of your steam boiler treatment program. Fuel usage, water usage, boiler efficiency, chemical tests, and stack temperatures are important indicators that must be monitored, but they mostly require trending of data over a period of time. Of course, when you take the boiler offline for your yearly inspection, you can see the condition of the boiler tubes for yourself. However, shutting down the boiler to perform visual inspections generally happens on a specified date.

It is also critical that daily water tests are performed to determine that the treatment program is working as intended. Dissolved solids levels, pH, alkalinity, iron, hardness, chemical treatment actives are just some of the basic water tests that diligent operators should be performing daily. But before a single drop of water gets placed in a conductivity meter or 25mL vial, there’s a simpler place to start.

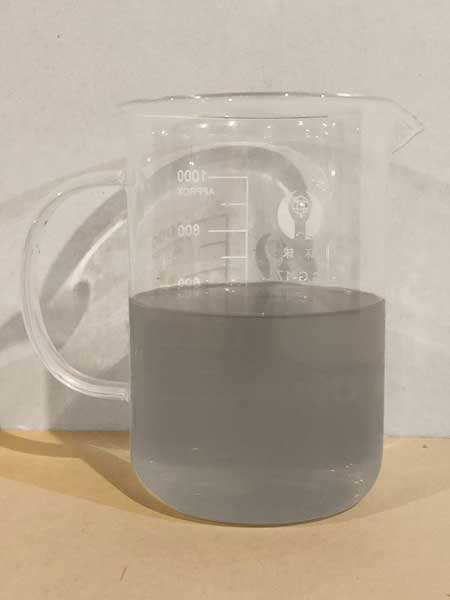

How does the water look?

It’s that simple. The first and easiest place to start is by examining the color and clarity of your boiler water.

Did you know that the water in your steam boiler system should be crystal clear? You may have grown accustomed to seeing discolored or rusty boiler water, to the point where it may seem normal. And whether your water is slightly discolored or is a rusty sludge, this can be a sign that the metal surfaces of your steam system have scaling and corrosion. Once that happens, many problems can occur.

Mechanically, corrosion causes your steam system to become susceptible to failure. This means unscheduled downtime and costly repairs. It also can greatly shorten the lifespan of your boiler, requiring you to replace the system much sooner than necessary.

Scaling and corrosion also negatively affect the performance of your steam boiler. It can lead to issues like steam boiler carryover, where liquid water and impurities are carried in with the steam and affect the steam quality and performance of your system. It often means that you use much more energy and water, driving up your operational costs and wasting these precious resources.

Proper water treatment is the key to stopping scaling and corrosion in your steam system

The right chemical treatment will ensure crystal clear boiler water and a clean boiler that will allow optimal heat transfer rates and a longer operating life. For too long it has been accepted that boiler water is always dirty, cloudy, muddy looking because that is all traditional chemistries could provide. Times have changed for the better with boiler treatment technology. Simply put, if the boiler water is not crystal clear, then your boiler water treatment program is not as effective as it needs to be and it is costing your facility money!

Assessing Your Boiler Water and the Potential Related Issues

The specific color or clarity of your boiler water can give you insight into the types of issues that may be happening inside your steam system. Unfortunately, none are good. Let’s examine some of the things you might see when inspecting your boiler water and what it could mean about your system.

Milky, Foamy Water

The milky color and foam could be an indicator of an excess of chemical feed contributing to high alkalinity in the boiler water. High alkaline water will lead to foaming conditions and is also a waste of chemical. Foaming can cause surging in the boiler and eventually to boiler water carryover.

As noted above, carryover means the system is creating steam that is no longer pure. This low-energy, low quality steam accelerates corrosion in heat exchanger coils, steam lines, and other equipment downstream of the boilers. It can cause a sharp drop in boiler efficiency, lead to water hammering and erratic boiler behavior, and make it difficult to manage any chemical program. In summary, carryover can seriously affect the operation and health of your entire steam system and greatly increase costs due to higher fuel use.

Dirty, Black Water, Possibly with Deposits

When you see a black color to the water, and possibly even black deposits in the water sample, it is a strong indicator of active corrosion of the metal throughout the entirety of the steam system. The tiny black particles and larger deposits could be transported from the condensate return lines and/or the feedwater tank itself.

The most common cause of pitting corrosion in boiler tubes is from dissolved oxygen entering the boiler. Makeup water to any steam system contains dissolved gases that become highly corrosive when heated inside the boiler. The first line of defense (at least in the past) is a properly operating deaerator and feedwater tank to liberate the dissolved gases mechanically before being introduced into the boiler.

Oxygen scavengers, such as sulfite, are then added to remove any remaining ppb of O2 before it can be liberated and attack boiler tubes. Traditional chemistries, however, have limited efficacy if you have a poorly functioning feedwater/DA tank. The amount of sulfite needed to combat high oxygen levels contributes to the dissolved solids of the feedwater, thus increasing the blowdown rate. More blowdown costs a facility in excess water and fuel usage.

In addition, any leaks in coils and steam/condensate piping will draw in air (oxygen and CO2) whenever a vacuum is created and accelerate the corrosion process. Due to this, flash and oxygen corrosion is of particular concern for equipment and, when left unchecked, results in costly failures and untimely maintenance.

Slightly or Extremely Rusty Water

Depending on how deep the color is, you could have a LOT of problems with your current program! Corrosion, high hardness, improper blowdowns, wrong chemistry…you name it! The contaminants in boiler water that looks like this are destroying your boiler tubes and condensate systems. This is akin to purchasing an expensive sports car and running it with old, used dirty motor oil!

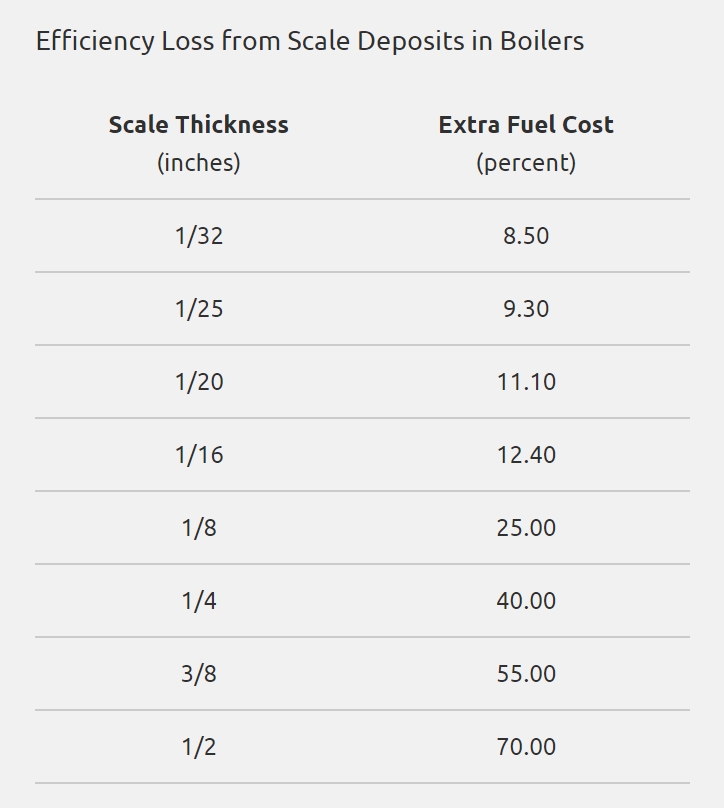

The contamination is increasing your fuel costs by causing scale deposits that are reducing the efficiency of your operation. How much? According to Johnston Boiler Company, a layer of scale even 1/16th of an inch thick can cause a facility to spend an extra 12% on its yearly fuel cost to run that boiler!

Clarity Has the Solution:

If your boiler water is not crystal clear, your facility is losing money running your boiler. As we said, the cleaner the boiler water, the cleaner the boiler and thus…the more efficient it will operate.

So if your boiler water isn’t crystal clear, what can be done about it?

A water treatment plan from Clarity will protect your system and have your boiler running at peak performance. Our proprietary technology, EcoSHIELD, is a cutting-edge treatment for steam boilers that is more effective, economical and eco-friendly than traditional chemical solutions. EcoSHIELD bonds to the metal surfaces of your steam system, protecting it from scaling and corrosion and extending the life of your equipment.

EcoSHIELD was designed to replace conventional water treatment methods and eliminate the use of chemicals that add dissolved solids to the boiler water. This greatly lowers the carryover potential of the water and significantly reduces blowdown, thus conserving energy and water and saving you money!

Just check the color of your boiler water and it will be clear that EcoSHIELD works!

If your boiler water isn’t crystal clear or you are experiencing other symptoms of boiler issues, give us a call. We’ll do a FREE evaluation of your boiler water and your entire steam system to see how a custom water treatment plan for your facility can save you money!

Download Our FREE eBook Today:

Ten Huge Mistakes Facilities Make in Boiler Operation and How to Avoid Them

Have a question about water treatment and steam boilers?

Check out our steam boiler resource page to find links to helpful articles and case studies that address commonly asked questions.