One of the most important issues craft brewers are trying to resolve is how to become more sustainable. While things like packaging and shipping pose environmental challenges, the brewing process itself generally consumes a great deal of energy and water. One of the main culprits is an inefficient steam boiler.

Ready for the good news? There is a quick and easy way to improve the efficiency of your steam boiler operation. A proper water treatment program can make huge gains in energy and water conservation during the brewing process. Not only does this help you become greener, it will also greatly reduce your operating costs!

An Eco-Friendly Solution for Steam Boilers

When it comes to running an efficient steam system, EcoSHIELD™ is the perfect fit for breweries. This is because most breweries use steam to heat brewing vessels with steam jackets, and thus, return most of their condensate, which we call ‘liquid gold’ in the water treatment industry. The ability to return condensate is the most significant factor affecting steam boiler efficiency for several reasons.

- Returning condensate means you have to take on less water from the city tap, saving on your water bill.

- Any city water taken on must first be softened. Taking on less water means you’ll use softener salt at a lower rate.

- Significant fuel savings occur as most returned condensate is relatively hot (130°F to 225°F) reducing the amount of cold makeup water (50°F to 60°F) that must be heated. Energy in condensate can be more than 10% of the total steam energy content of a typical system.

- Condensate is as pure as the water gets, essentially distilled water containing low levels of dissolved solids. The fewer solids you add to your boiler, the less often you have to blow it down, saving water and sewer costs.

Why EcoSHIELD™?

EcoSHIELD™ is an example of Clarity’s ability to develop unique blends tailored to a customer’s specific water treatment needs. It is an enhanced chemistry that protects the metallurgy of the entire steam system and allows greater conservation of water and fuel than traditional chemical programs. It is one of the most effective, state-of-the-art, and environmentally-advanced water treatments on the market.

Why is EcoSHIELD™ an ideal fit to use in systems that return the majority of its condensate like Craft Breweries?

- EcoSHIELD™ can be recycled through the condensate return, requiring you to feed less chemical into the feedwater tank.

- EcoSHIELD™ keeps heat transfer surfaces (inside the kettle and hot liquor tank steam jackets) clean and has even been shown to assist heat transfer better than a bare metallic surface.

- EcoSHIELD™ doesn’t contain any solids, further reducing boiler blowdown frequency.

Protecting Your Equipment from Corrosion and Scale

In addition to what EcoSHIELD™ does differently to boost boiler efficiency, all boiler treatments aim to limit the corrosion of the system and prevent scale from forming on the boiler tubes. There not a more effective way to treat a steam system than with EcoSHIELD™ due to the protective passivation formed on all metallic surfaces it touches. Lengthening the lifespan of your steam system and the steam side of brewing equipment saves lots of money in the long run. Preventing scale formation on boiler tubes is manageable with a water softener and an effective boiler treatment like EcoSHIELD™, but it can become very costly if left unchecked. By insulating the boiler tubes, scaled boilers have to use more fuel to achieve the same level of heat transfer. A mere 1/8th inch of scale requires a fuel increase of 25%!

See the Results: A Brewery Case Study

A great example of a brewery taking advantage of the efficiency gains afforded by using EcoSHIELD™ is Rhinegeist Brewery in Cincinnati, Ohio.

Clarity has been a fantastic partner in maintaining our boiler chemistry and I recommend Clarity to everyone I know installing a steam system.

Cole Hackbarth, Rhinegeist Brewery

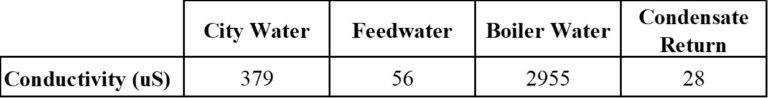

An analysis of the water testing data gathered at Rhinegeist demonstrates just how efficiently their boiler operates. Below is a chart showing the conductivity of water collected at different points of interest in their system. Conductivity is a measure of how easily the water can carry an electrical current and is a good measure of the number of solids present in the water sample.

As mentioned previously, the condensate is the purest water in the system. The feedwater is a blend of condensate return and city water, but it is still very pure since Rhinegeist consistently returns over 90% of their condensate. The day this data was gathered, their feedwater consisted of 92.02% condensate and 7.98% city water.

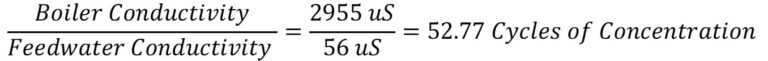

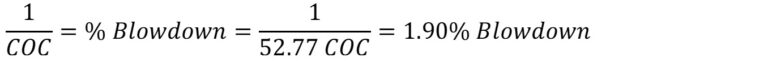

Cycles of Concentration (COC) is another good way to gauge boiler efficiency. It is calculated by dividing the conductivity of the boiler water by the conductivity of the feedwater. This essentially tells you how many cycles the feedwater can be reused before the boiler needs to be blown down to remove solids that have accumulated as steam is driven off. By calculating COC, you can also do a quick calculation for blowdown percentage.

We aim for 50 COC in the boiler because there are diminishing returns on efficiency once you start getting higher than 50 COC, making running higher cycles not worth it unless local sewer costs are expensive.

In addition to the energy savings Rhinegeist has made, their steam system and brewing vessels are being protected against corrosion exceptionally effectively. Iron oxide corrosion can never be completely stopped, only slowed; thus, the American Society of Mechanical Engineers (ASME) sets the guideline for effective corrosion control at an iron concentration of 0.10 ppm in the boiler feedwater. Our goal is to be below this number, and with EcoSHIELD™ and proper boiler operation, that is the norm. The feedwater iron level upon the most recent data at Rhinegeist was 0.02 ppm, which is the lowest the iron measuring device can read before hitting zero. Iron was also tested in the condensate, which is the most corrosive water in the steam system (because it’s so pure and wants to dissolve anything it touches), and the result was also 0.02 ppm iron.

How Clarity Can Help

In addition to the advantages EcoSHIELD™ affords in returning condensate and protecting against corrosion, it is unmatched in its ability to increase energy efficiency and save money. For an industry that cares deeply about green initiatives, EcoSHIELD™ is a straightforward way to reduce water, fuel, and effluent loading costs.

Clarity has extensive experience with boiler operation in brewing applications. We will do a FREE evaluation of your entire system to ensure your water is properly treated and you are operating at peak efficiency. To schedule an evaluation, or if you are experiencing any problems or have questions, please contact Clarity Water Technologies today!

Download Our FREE eBook Today:

Ten Huge Mistakes Facilities Make in Boiler Operation and How to Avoid Them

Have a question about water treatment and steam boilers?

Check out our steam boiler resource page to find links to helpful articles and case studies that address commonly asked questions.